The University of Veterinary Medicine saves a month and hundreds of euros for getting a brain-cutting template using RangeVision Spectrum 3D scanner

Goal: to 3D print a brain-cutting template for a research of the University of Veterinary Medicine (Vienna) and save a month

Solution: RangeVision Spectrum, rotary table TS, ScanCenter NG, Autodesk Fusion 360, Formlabs Form 3

Summary: A pig brain was 3D scanned with RangeVision Spectrum 3D scanner. The obtained 3D model was used for further processing and preparing of an object for 3D printing. After 3D printing a brain-cutting template was post-processed to get a higher level of firmness. As a result, specialists got a template saving up to 6 weeks of the delivery time and up to 2000 euros.

3D printing and 3D scanning technologies continue to spread in both medicine and veterinary science. Our partner 3Dee got an order from the University of Veterinary Medicine in Vienna to create a template for cutting pig brains.

The University studies brain segments of domestic pigs in one of the scientific researches. Organs must be separated for such studies very carefully. The studied “material " is very soft and delicate, that is why special templates for the procedure are used to avoid unnecessary damage.

The cost of specialized templates made of aluminum varies from 1000 to 2000 euros, and the delivery time is up to 6 weeks.

Unlike traditional templates, a 3D printed version is ready for use within maximum 14-16 hours and costs significantly less than milled versions.

To get a 3D printed template there were a few steps to go. They included 3D scanning an object, a 3D model generation of a future template, 3D printing and post-processing.

For 3D scanning specialists picked RangeVision Spectrum 3D scanner which allows digitizing objects with the 3D resolution of up to 0.06 mm and the accuracy of up to 0.04 mm. It’s particularly suitable for science and research purposes.

Step 1: 3D scanning of the brain

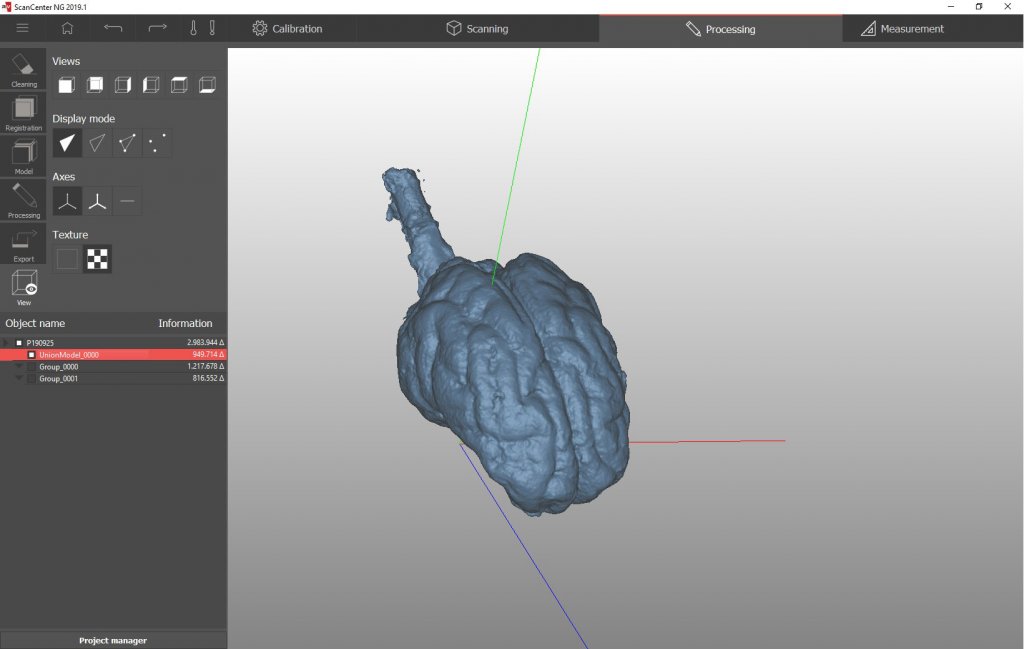

A pre-cooled to 0° C brain was placed on the automatic rotary table TS. The surface of the organ was relatively homogeneous, but allowed some of the projected light to pass inside. To get the best 3D scanning quality, the double (contrast) illumination function was enabled and a special black substrate was used.

The brain was scanned 360-degree two times in 20 minutes. After 3D-scanning, the results were processed in ScanCenter NG software. It took about 10-15 minutes. The final model was saved in STL-format.

-

3D scanner: RangeVision Spectrum 3D scanner

-

3D resolution: 0.12 mm

-

3D accuracy: 0.03 mm

-

Time: 30-35 Minutes

-

Software: RangeVision Scan Center

-

Post-Processing: RangeVision Scan Merge

-

Rotary table: TS12

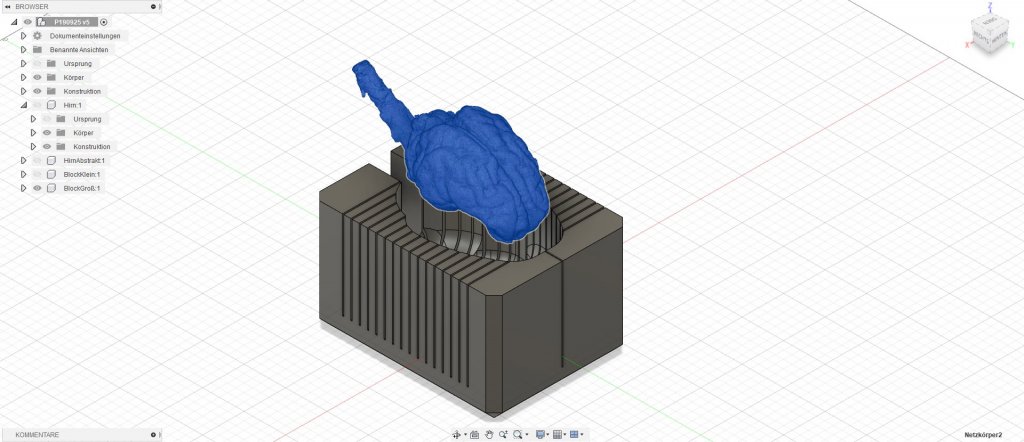

Step 2: Modeling

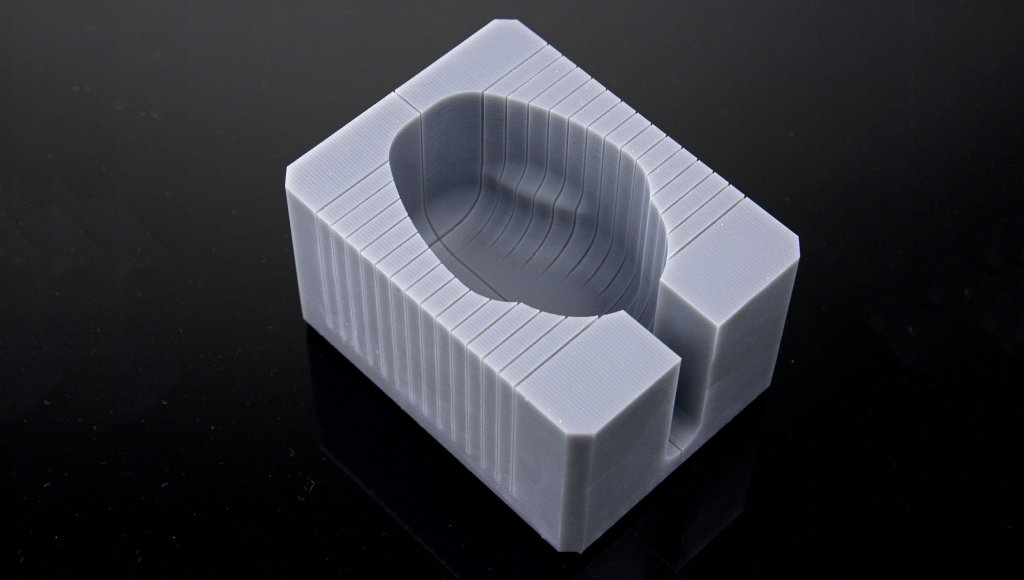

The obtained 3D model in STL was imported to Autodesk Fusion 360 to finish the model of the template for cutting brains. The whole process took about 2 hours. The width of separated template segments was 5 mm, the gap between them was 0.6 mm (the thickness of the cutting blade was 0.5 mm). The template was exported to STL-format and prepared for further 3D printing.

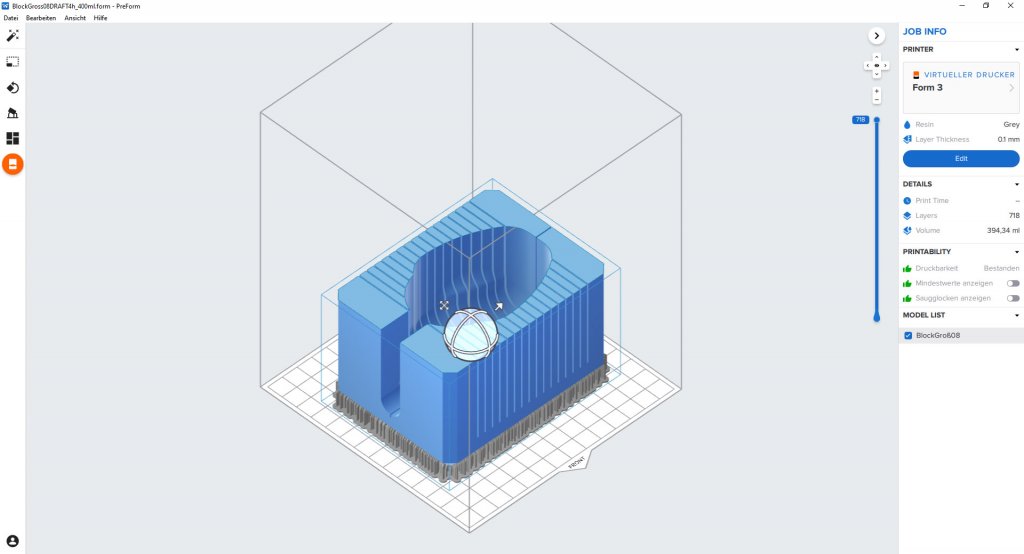

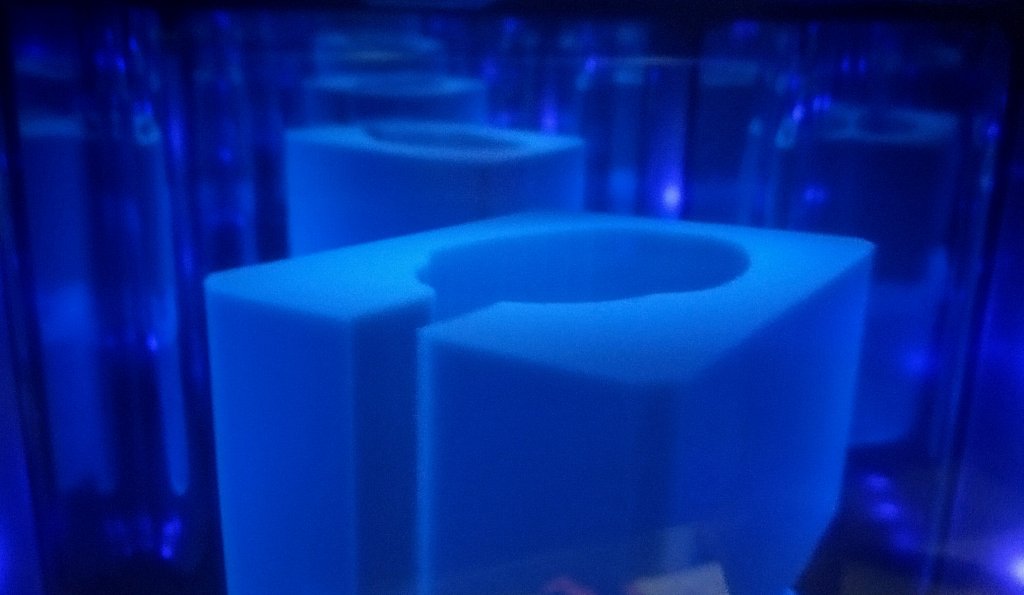

Step 3: 3D printing

The template model was printed using LFS (SLA) technology on a Formlabs Form 3 3D printer with the set resolution of 0.1 mm. The process took about 10 hours.

The template must have a certain strength level, so it was printed completely filled. It took 394 ml of Formlabs Gray Resin material total cost of € 51.87.

Step 4: post-processing of the printed model

To ensure the maximum possible service life and firmness, the 3D printed template was subjected to temperature (80° C) and UV (405 nm) processing in FORM CURE.

Final result:

Specialists spent about 11 hours on the process of creating the template in total and saved about 6 weeks of waiting when ordering conventional templates. In that way, the University was able to have low-cost templates in a very short term that was the perfect solution.

Additive technologies are changing our lives in real time. Now it’s no need to wait for weeks to receive needed parts for your work. 3D scanners and 3D printers make us able not only significantly save our time but also save our money. It goes for all the spheres including business, science and hobbies.